ThermoClad VS Alternatives

What are the existing alternatives for outdoor ventilation insulation protection?

Alternative 1: Glass Fab & Mastic (tar)

This is a very old technique for outdoor ventilation insulation protection. Insulation was applied, followed by a layer of mastic (tar) toweled to the insulation, followed by a glass fab mesh applied/embedded to the mastic (tar) followed by a final layer trowel coat of mastic (tar). This application is still being used to date. It is plagued with leaks from the date of installation, and has no ultraviolet / ozone resistance. It is a very messy application with a very unappealing appearance. This application has been around for approximately 40+ years.

Alternative 2: Aluminum Jacket Applications

This is another very old technique for outdoor ventilation insulation protection. Insulation is applied, then an aluminum or stainless steel clad finish is applied over the insulation The cladding is being applied flat to all four sides and affixed to the insulation with foil tape.

The four sides (corners) of the cladded ducting now have matching corner beading applied and fastened with screws all around, followed by a bead of silicone caulking applied to all the joints.

The corner bead along the top corners restrict the watershed causing water to saturate the joints and screw penetrations; the joints break open over time causing leaks, the screw penetrations cause the screws to pop during the freeze/thaw seasons. The screws are never sealed causing seepage of water from the date of installation. The aluminum also distorts and warps to the winter /summer heat changes also cause joints to break.

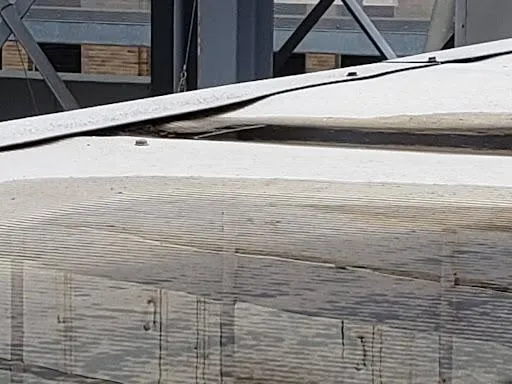

Below are pictures we took of aluminum and insulation being replaced at a facility due to condensation and water penetration.

Alternative 3: Foil face tape type applications

This is the newest to date option for outdoor ventilation insulation weather protection. This foil face tape type application is essentially a 2’ - 3’ roll of embossed foil tape. It is applied by a peel and stick application. The downside flaw to this product is the birds will peck holes through the product easily. Also the joints would tend to peel back over time and would require silicone to be added over the joints. Very easy to puncture or dent.

The picture below shows patches over patches from bird strikes. The maintenance staff resorted to putting fake owls to deter the birds from damaging the jacketing system. It appears their effort and ideas didn’t work.

Why is ThermoClad better than the existing alternative application?

ThermoClad is the current newest and revolutionary alternative to date which uses up to date Thermoplastic Olefin (TPO) Technology over the old existing alternatives for an all-weather rooftop ventilation insulation protection for a number of reasons.

If you need to replace your current jacketing system that has failed due to the flaws listed above. What options do you have?

Would you replace it with the oldest and messy application; Glass Fab & Mastic (tar)? No.

Will you replace it with the high cost of aluminum cladding with screw/rivet holes and caulking joints that failed?

Would you put screws in the roof of your home? No.

Would you replace it with a foil tape type jacketing system that the birds peck holes through the product? No.

Those are your only old obsolete alternatives of their time.

ThermoClad is the newest application using the newest Thermoplastic Polyolefin (TPO) Technology. ThermoClad is the only all-weather rooftop ventilation insulation protection that comes with a manufacturer warranty for 10 year UV resistance. The ThermoClad wrap system has been tested and installed in Manitoba Canada for the past 6+ years with zero call backs or complaints.

Over that time the temperatures in Manitoba range from +40 C. in the hot summer months and -40 C in the winter months.

ThermoClad continues to perform and and exceeds expectation. See the project pictures below for yourself and you decide.

What is TPO?

It is a waterproof sheet membrane which consists of a reinforced continuous polyester fibre arranged in a grid or in a mat sandwiched between to sheets of flexible matrix, a kind of polymer water proof material which is made of advanced processing technology. TPO membranes both the ethylene propylene diene rubber weather resistance, aging resistance and polypropylene weld ability. One of the properties of thermoplastic membranes is that the material temporarily changes from a semi-solid state when heated sufficiently, enabling the sheets that are overlapped to be fused together and return to a solid upon cooling. Thus, a monolithic, continuous sheet membrane is created. Thermoplastics is widely used in the roofing industry as a waterproof membrane.

Advantages of ThermoClad Ventilation Weather Protection:

Due to ThermoClad’s unique design we eliminated the heat-weld process saving time and added labor costs.

Other benefits include:

✔ Easy peel and stick application.

✔ Weather resistant.

✔ Anti ultraviolet, ozone resistant.

✔ High puncture & impact resistant. (excellent tear resistant).

✔ Inherently fire resistant.

✔ Water resistant.

✔ Low temperature resistant (remains flexible at low temperatures).

✔ High temperature resistant.

✔ Resistance to solvents, oils, acids, and detergents.

✔ Resistant to bacteria & fungus/mold growth.

✔ Easy to bend and manipulate around “inside/outside” corners and shapes.

✔ Aesthetically appealing.

✔ Provides excellent visual feedback of workmanship during and after installation.

Applications:

ThermoClad is the ultimate solution for professionals who demand the highest standards in weather protection and durability. It offers versatility and adaptability, making it perfect for a wide range of applications, including:

✔ Outdoor Air Ventilation Systems: Protects exterior insulation from the elements.

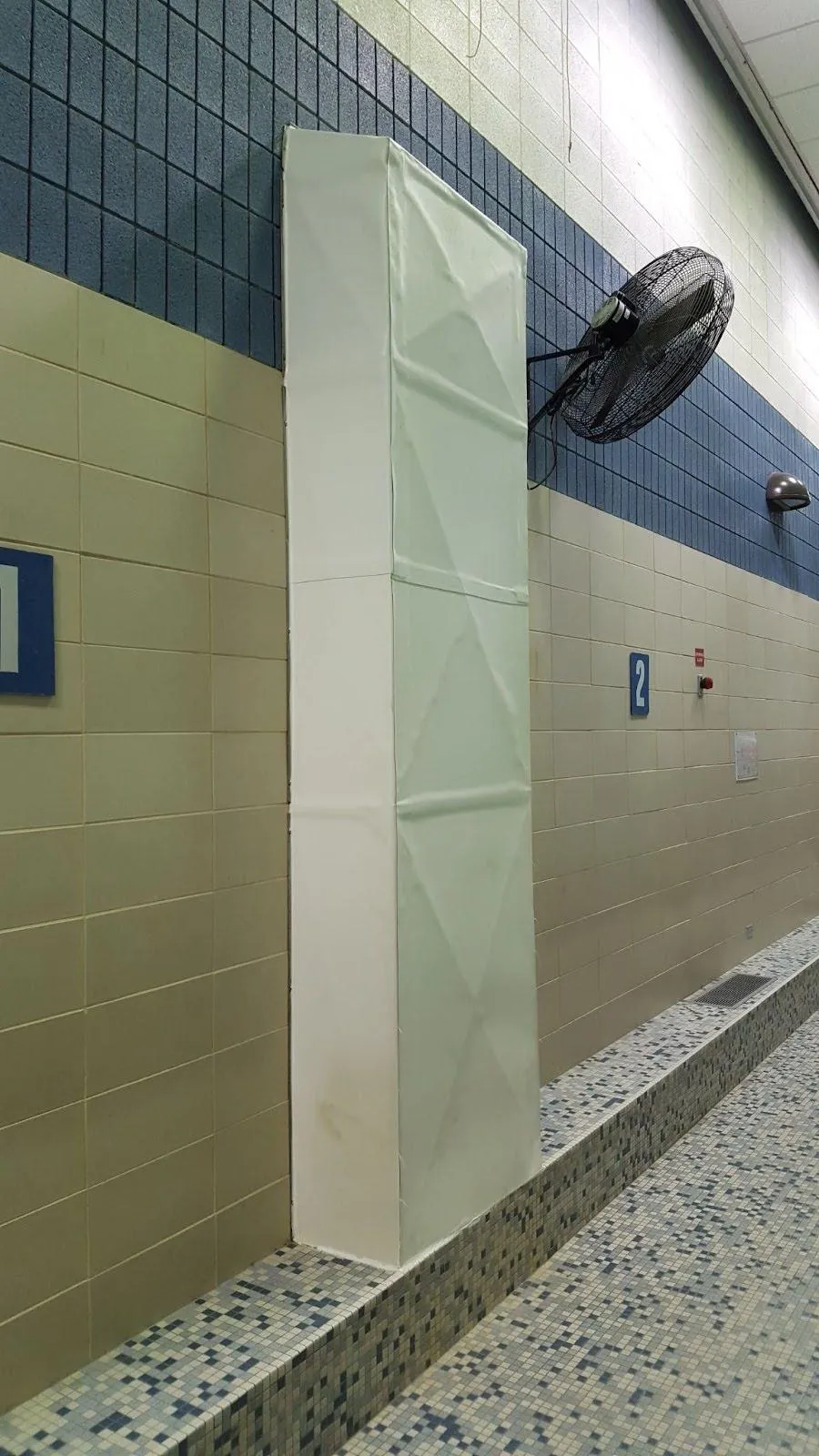

✔ Indoor Ventilation Systems: Ideal for environments like indoor swimming pools where moisture control is critical.

✔ Cargo & RV Trailer Roofs: Ensures lasting protection against weather exposure.

✔ Walls & Structures: Wherever waterproofing is essential, ThermoClad provides reliable coverage.

Recommendations:

ThermoClad recommends insulation products for exterior ventilation systems as a Foil-Faced Polyisocyanurate foam board (ISO board) rather than the traditional fiberglass FSK rigid board insulation for a number of benefits.

The number one factor being ISO foam board at a 2” thickness has an R-value 12-13 as opposed to the traditional FSK fiberglass rigid board at a 2” thickness has an R-value of 8-9 saving energy costs and equipment.

The second advantage of using ISO foam board rather than the traditional fiberglass FSK rigid board; ISO foam board will not retain water as with the traditional fiberglass FSK board.

The third benefit being ISO foam board will not mold or mildew as is the case with the traditional FSK fiberglass rigid board.

The fourth benefit is that the ISO foam board will not compress under snow load as is the case with the traditional FSK fiberglass rigid board. Foil-Faced ISO board is easily foiled taped at the corners and butt joints to create a complete vapor barrier seal.

These benefits will facilitate the lives of mechanical engineers, mechanical contractors, and the end user. All from using Polyisocyanurate ISO foil faced foam board over the traditional FSK fiberglass board. Combining Polyisocyanurate foam board (ISO board) with ThermoClad all-weather ventilation insulation protection that has a 10 year manufacturer warranty for UV resistance you will have the newest revolutionary 🍁 innovative way for rooftop insulation weather protection to date.

This system would also be beneficial for coastal sea cities with sea salt corrosion problems to exterior ventilation systems. ThermoClad will not deteriorate due to sea salt corrosion thus protecting the metal beneath. Below are project pictures completed with Polyisocyanurate foam board (ISO board) and the products we have used and recommended.

Connect

Proudly Owned & Operated In Canada

© Thermo Ventwrap Inc, 2025

All Rights Reserved - Built with BlackBeltConnect